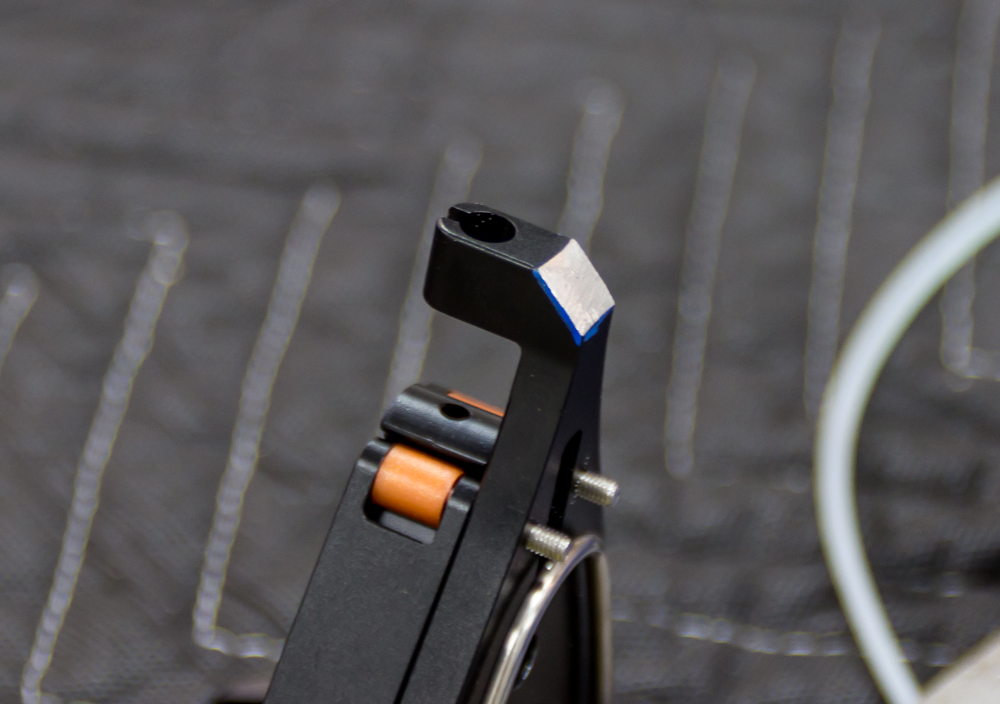

Unfortunately, they gave me the piece below on the right. That's a cable stop for the rear brakes on the top tube. I needed the piece on the left for the rear derailleur shift cable. I didn't realize this until I returned home and tried to stick the brake stop in the derailleur hole.

I was sad. The shop is 20 miles away. Nevertheless, I got back in the car and drove back out again and got the right part. Honestly, I was just glad they had the correct piece at all.

Flo 60 Carbon Clincher for the rear. 11-spd SRAM PG-1170 11-28t cassette.

SRAM PC-1170 chain. The method for sizing the chain is a bit different from standard, to account for a larger range in the cassette.

Flo includes their own proprietary brake pads for use on the carbon rims. Use of other pads voids the warranty.

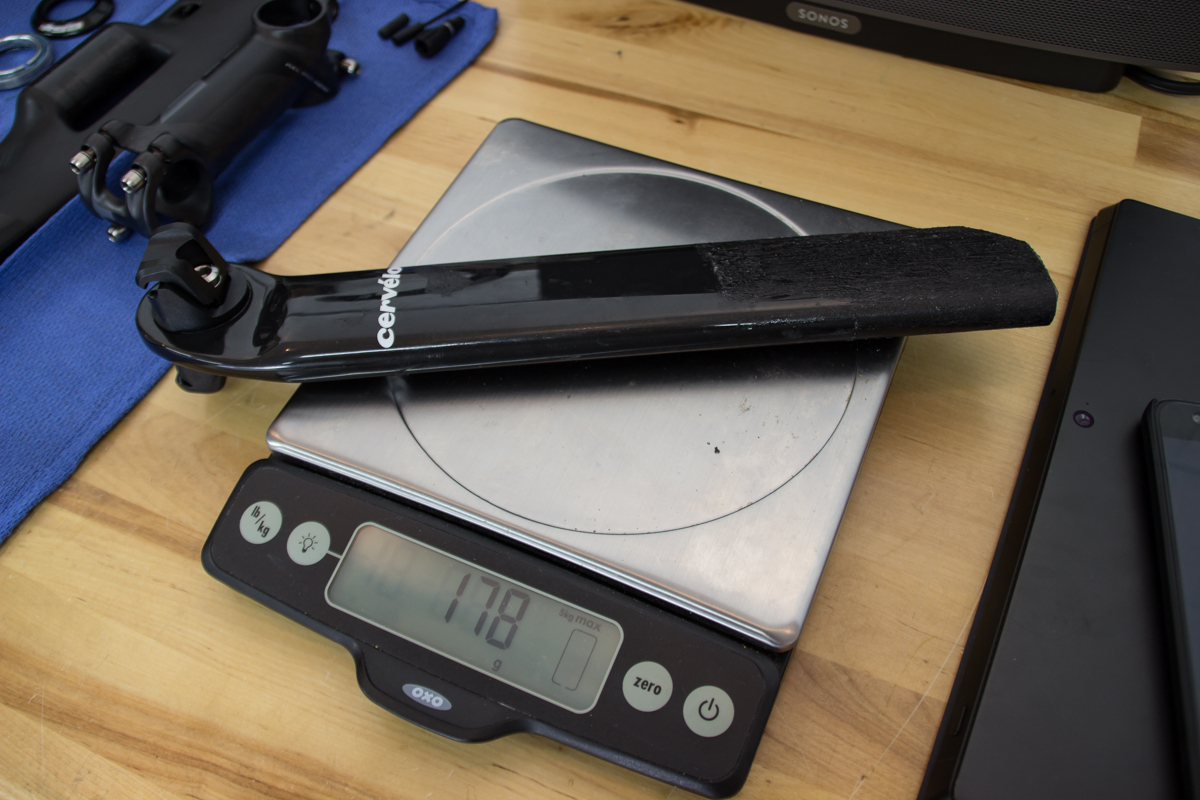

I'm still not sold on the fizik Arione seat, but I'm moving it over from the Allez anyhow.

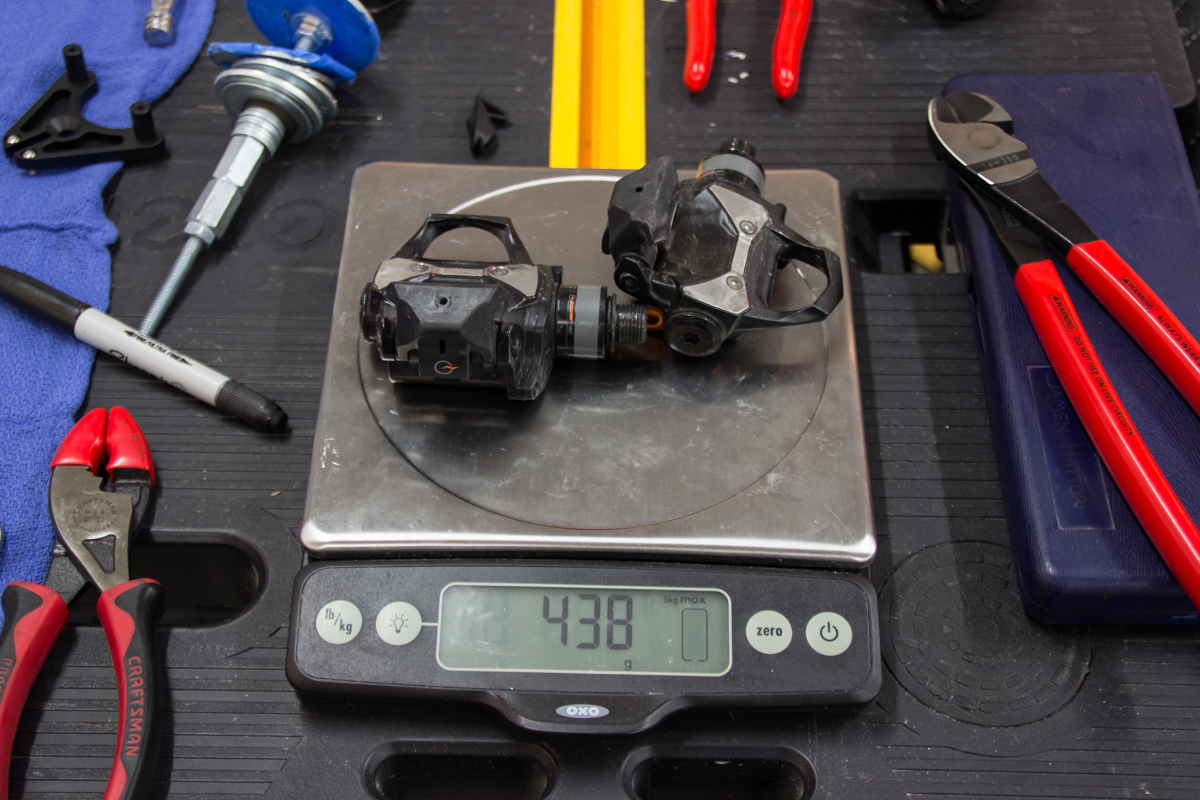

The Powertap P1 pedals are incredibly heavy. The Look Keo Carbon Ti Blade pedals I have are less than 200g for the pair. Good thing the P1's work well and are so convenient.

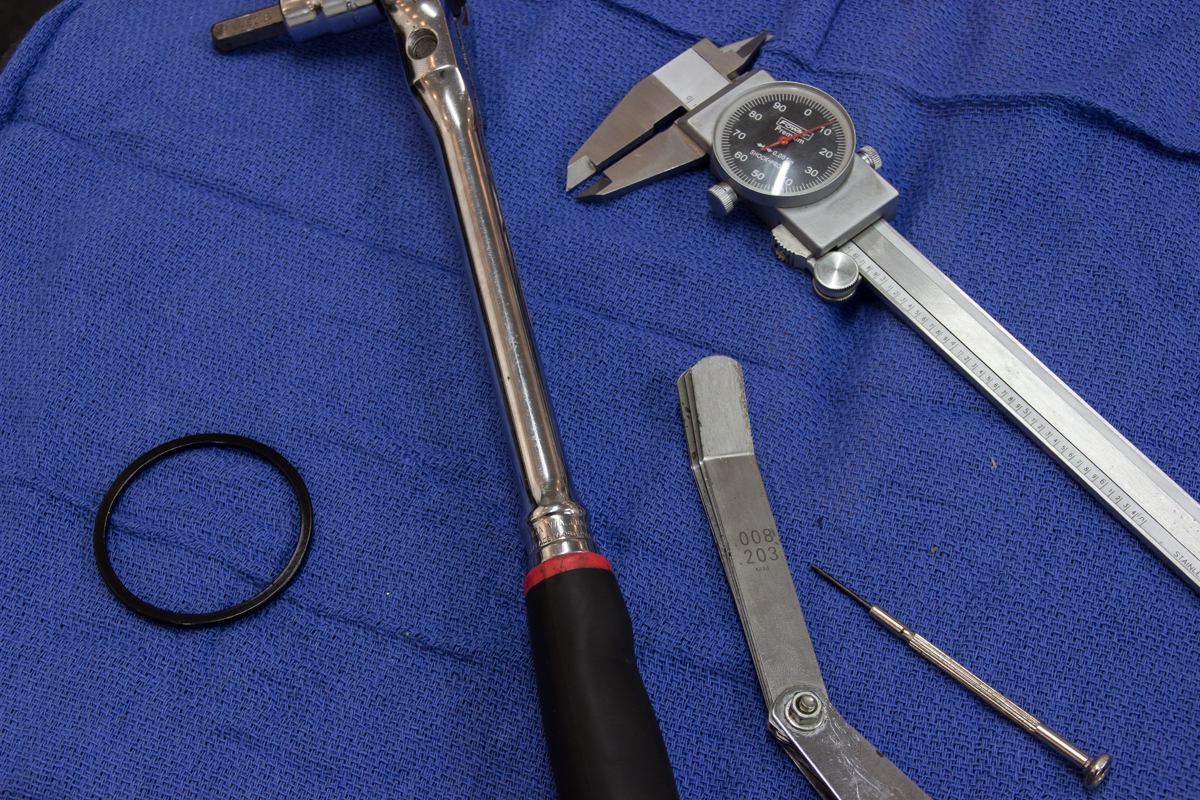

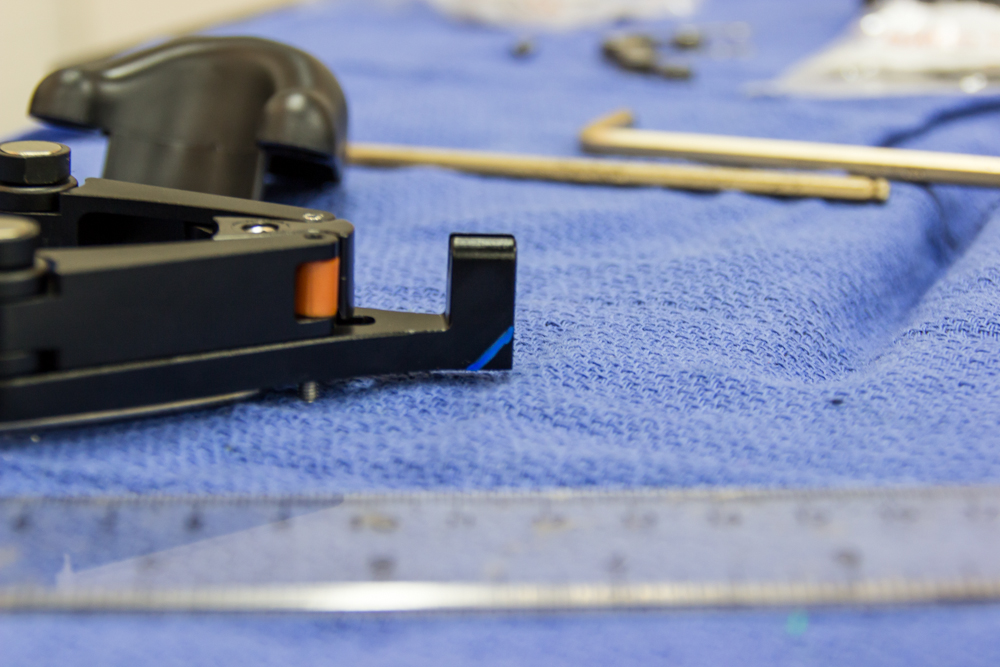

I regularly go on 100 mile rides and generally experience discomfort at some point. I found that adding massive amounts of padding and cushion to the handlebars helps. I use fizik's gel inserts and Lizardskin DSP 3.2. This setup adds a horrific amount of weight, but it's a sacrifice I'm willing to make.

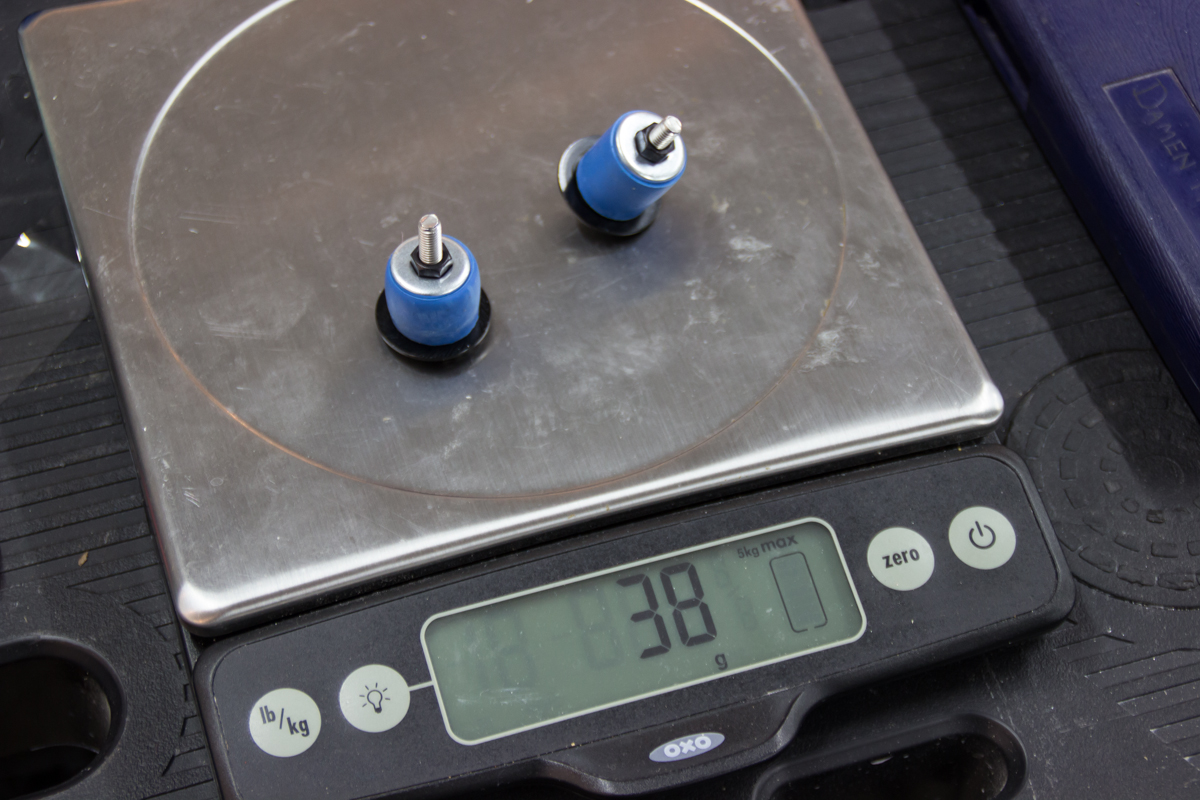

I always have a difficult time with the bar end wrapping on the DSP tape. It's very thick and doesn't stretch. I found that the expanding type bar ends stay in, and the push-in type don't. I'm sure it's due to my poor technique.

And it's ready to ride! The only thing left is to trim the steer tube, but I want to make sure I like the position first; it's a massive change from the Allez.

Cheers!