Step 1: I want to 3D print something large.

Step 2: Discover there aren't any realistic large format 3D printers.

Step 3: Make one yourself.

It's a familiar template to those who follow the maker / startup culture. "I want something; it doesn't exist; I'll make it myself".

A friend at my day job, Jason, has fostered an ambitious design and manufacturing hobby to the point of stand-alone profitability, specializing in reproducing and improving various parts for obscure European cars (I'm sure he'll argue against my use of obscure here). He's been involved in machining, both manual and CNC, since he was mentored by his father in the craft as a kid. I have my own storied history with obscure European cars (racing an Alfa Romeo in college), and my dad is a machinist too, so we became fast friends when we met. Admittedly though, our paths have diverged a bit: while I may be pretty handy with a Harbor Freight drill press, I managed to learn effectively nothing about machining from my father, and have happily, resolutely, relegated obscure European cars to my past.

I've followed Jason's exploits for the last few years, including his recent linking up (through a brief foray into the world of digital currency mining [a.k.a.Bitcoins]) with another entrepreneurially minded engineer named Andrew. Andrew was recently employed in the medical engineering space, through which he gained three-dimensional (3D) printing experience.

Briefly, I'll try to give a quick explanation on 3D printing: it's like drawing with toothpaste. Imagine you wanted a miniature replica of an Egyptian Pyramid. You would first squeeze out some toothpaste in the shape of a square, then fill it in. Now you have a toothpaste square.

Next, you draw another square, only a little bit smaller, on top of the first square. Then again, a smaller square on that. Then again, until the final square you draw is just a dot of toothpaste on top. If you are as bad at toothpaste painting as I am with Microsoft Paint, then your Great Toothpaste Pyramid would look pretty lousy, like the one below. But hopefully it gets the point across.

An extrusion-type 3D printer (which is what we're talking about here) does the same thing, except it's a robot doing the drawing, and it doesn't use toothpaste, but some type of meltable material, like plastic. The robot pulls in some plastic from a spool, melts it, draws with it, the plastic hardens, then the robot moves up a little and draws another layer. There are other styles of 3D printers, but those are outside the scope of what we're talking about today.

Back to Jason and Andrew. After doing some experimenting with an available 3D printer, they came to the realization there weren't any solutions on the market to print large designs. The most popular and familiar 3D printer company, MakerBot (which is now selling at Home Depot), makes a printer that can create an item as large as 1 ft. x 1 ft. x 1.5 ft. high, but they wanted something bigger. Like 3 ft. x 3 ft. by 3 ft.

So they made one.

I had seen some prototype pieces in the early stages when visiting Jason's shop, but hadn't been over in many months; I was due for a visit.

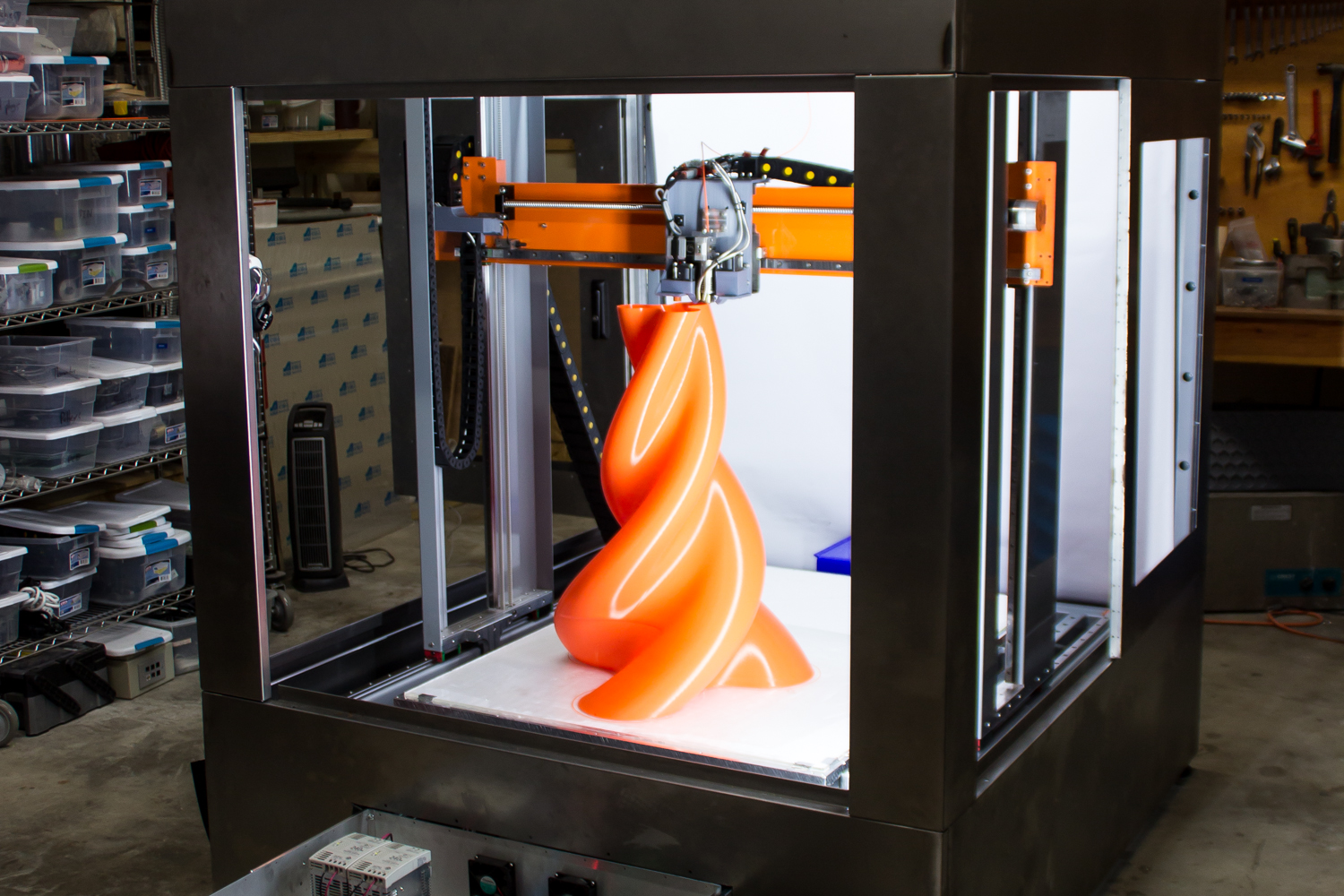

I walked in to check out the fully functioning prototype, developed and manufactured under their new company name, Cosine Additive.

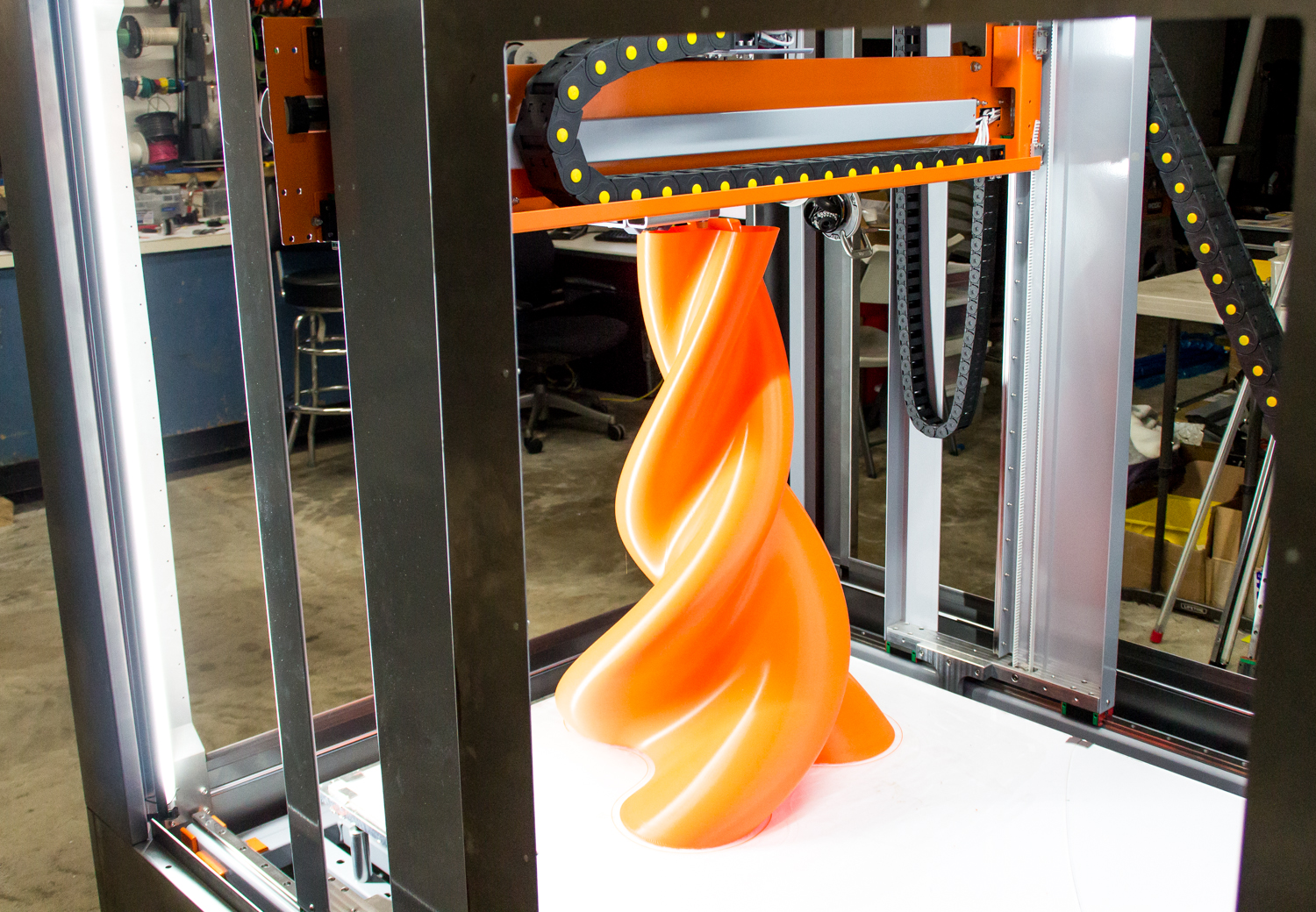

They were about 70% through printing a demonstration part on their AM1 prototype. This hollow orange design would be nearly impossible to create on a traditional machine, making it a "show-off" part to help market the printer.

This is a close-up of the print head. As it moves back and forth along the silver ball screw, it draws in the orange plastic from a spool at the rear of the machine, melts it, then extrudes (or "squeezes") it out of a precisely sized nozzle. The plastic hardens within a few seconds after.

The large grey block holding everything together is a prototype piece that they actually printed on a small commercially available printer. The production version of the machine will have a solid metal piece.

They had a number of spools on a cart behind the machine from which the printer pulls material. Jason is the guy in the striped shirt.

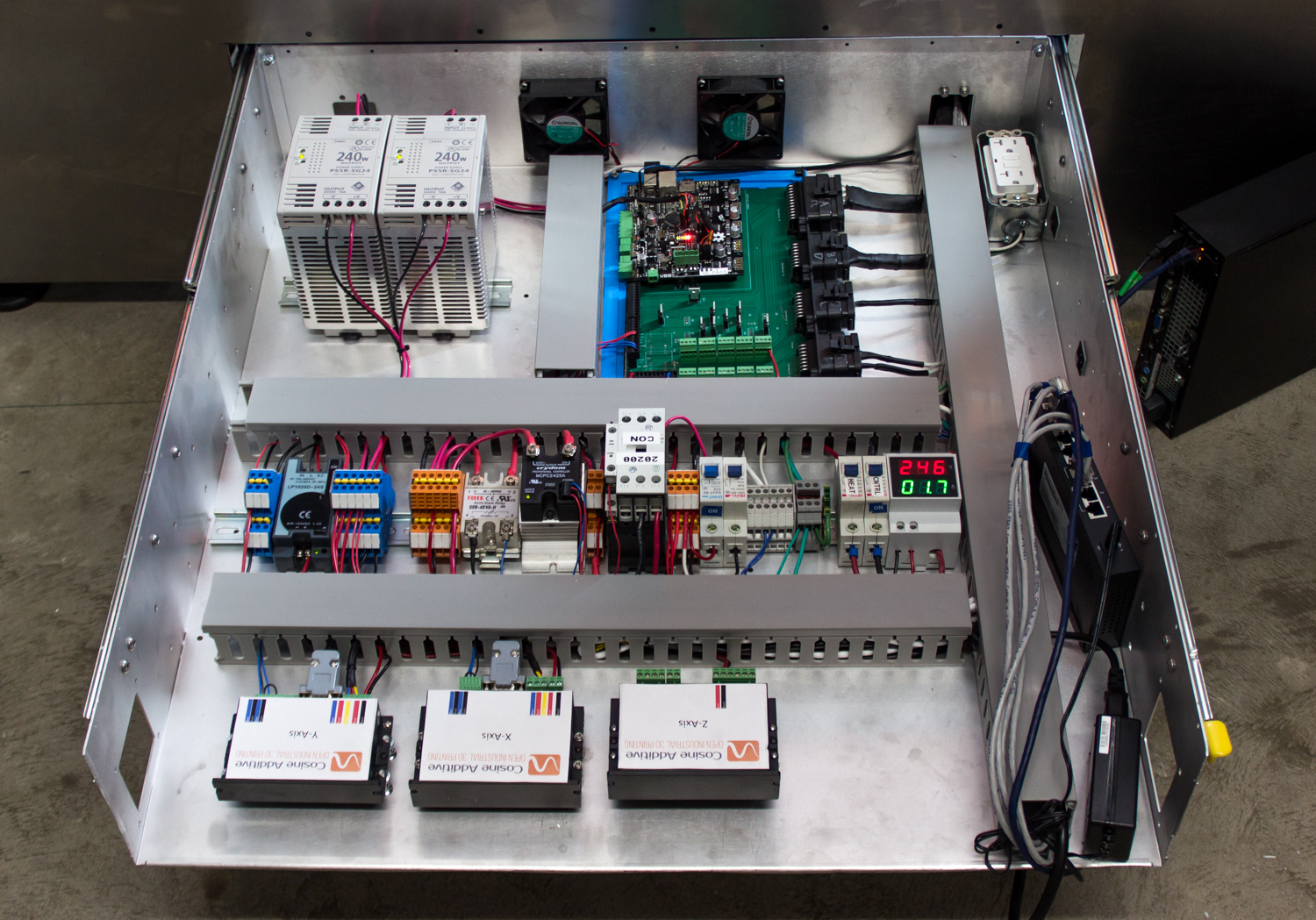

The power feeds and controllers are really nicely laid out in a sliding tray beneath the print area.

Since my visit, Jason and Andrew have made a number of improvements to the machine as you see in this post and taken it to a number of trade expositions where the response has been excellent. Good luck guys!