My brother wanted to get rid of his 2005 Saab 9-2X Aero, so I offered to detail it for him to make it a bit more presentable.

It lived a bit of a hard life, outside in the mean elements of Rochester, NY. Here's a before picture. This is right after being washed. You can see the paint has some heavy etching and swirl/scratch marks:

The process to get this thing cleaned up was pretty straight-forward, although massively time-consuming.

Step 1: Wash with Dawn.

Step 2: Clay bar with Meguiar's detail lubricant.

Step 3: Meguiar's 105 Ultra-Cut compound on Lake Country Orange pad with Porter Cable 7424XP Dual-Action polisher.

Step 4: Meguiar's 205 Ultra-finishing polish on Lake Country Black pad with Porter Cable 7424XP Dual-Action polisher.

Step 5: Finish with Rejex Polymer Paint Sealant on Lake Country Black pad with Porter Cable 7424XP Dual-Action polisher.

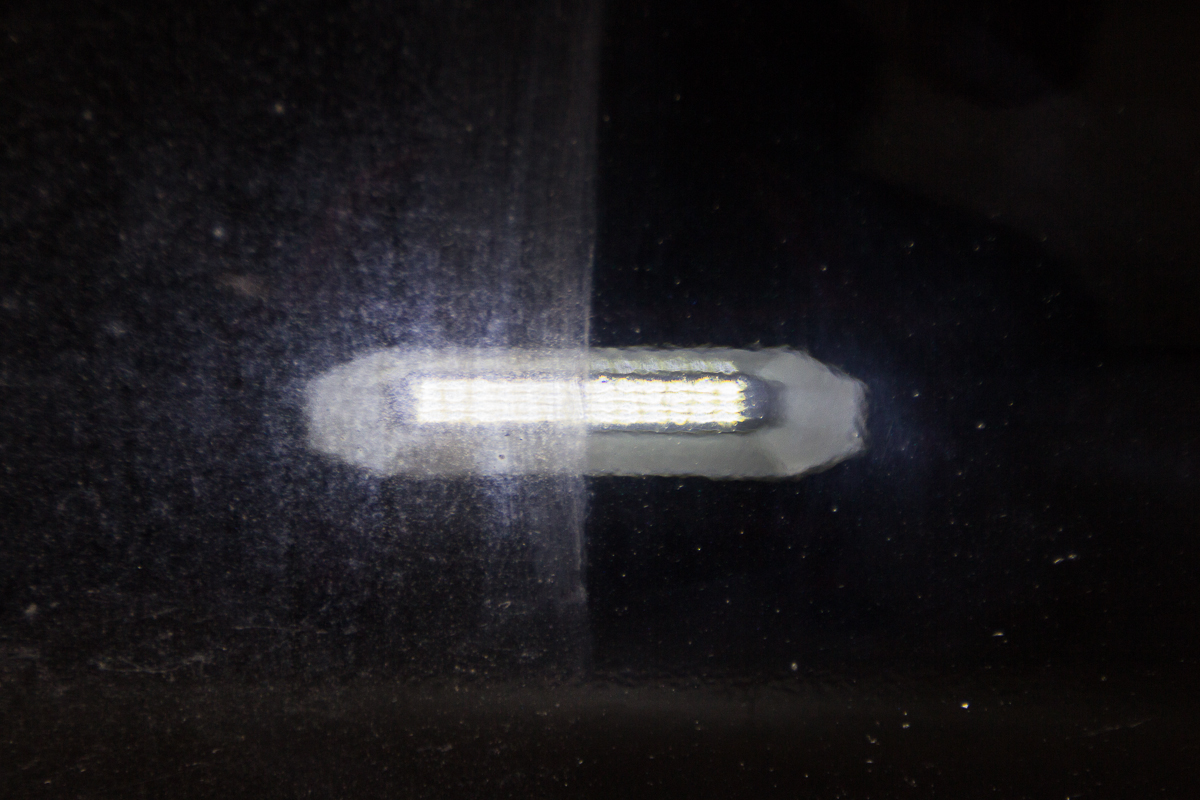

This is what they call a "50-50" shot. The left half is post-wash, but before any other steps (between Steps 1 & 2). The right half shows after all the polishing, and before the final sealant (between steps 4 & 5).

All finished!

The reflections here show a much smaller amount of defects in the paint. I didn't get it perfect, but probably 90% of the way there.

Some outside shots. Unfortunately I finished later in the day, so I couldn't get the sun reflection pictures to really show the state of the paint. However, since I didn't get it perfect, maybe that's better.

Interior. Didn't do much here, just a vacuum and wipe-down with some conditioner.

Low mileage:

The car looks a lot better. Hopefully it will sell quickly.